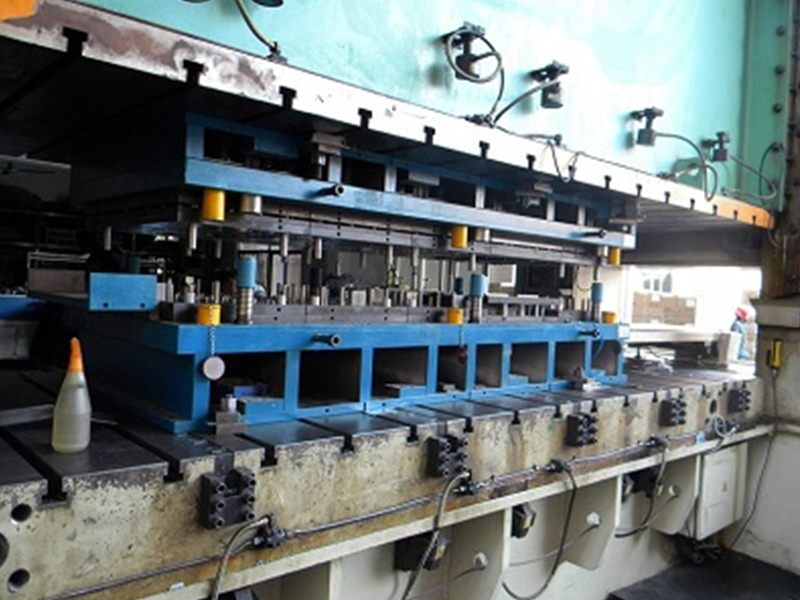

1. Put the tool on the press, and open the tool.

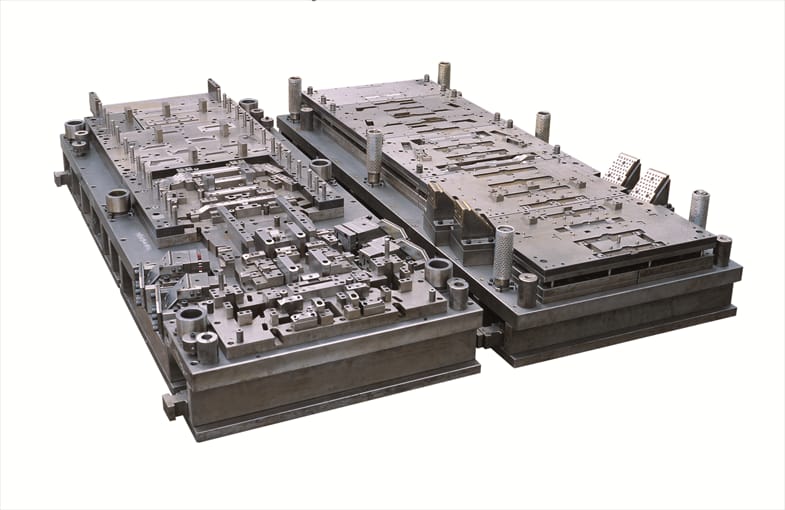

2.Put a small piece of material which thickness is same to the part into the tool. The material should be smaller than the area of die plate so the tool do not bend the part.

3. Move the slide upwards to the upmost point, then lower the slide to the down point.

4. There is an adjustment of the slide, adjust it until the upper and lower die closed totally.

5. Check the reading of the shut height. It might be smaller than the shut height we offered as we read your description.

6. Use the shut height you just got to stamp the part.

Shut height needs to be found out every time you use a new tool since the supplier’s press is different. The shut height we offered should be used as a reference data when you set up the tool.