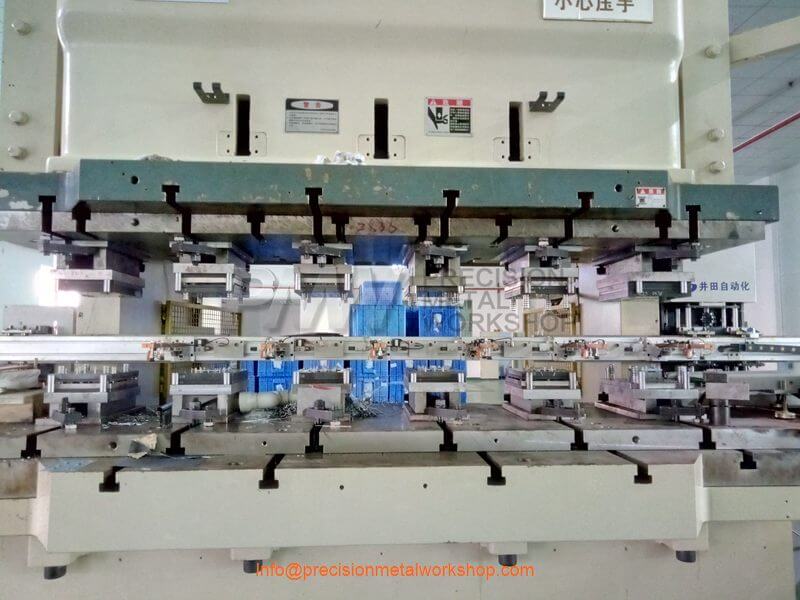

Precision Metal Workshop is professional at both high volume, tight-toleranced precision metal stampings like GPS navigator back panel of automotive, using progressive stamping or automatic transfer stamping; and lower volume single hit productions for various industries. The precision stamping production begins with high quality progressive dies/transfer dies we built in house.

Our presses are equipped with infra-red and other sensors, withclose tolerance material feeders, allowing us to run production consistently and safely at maximum speeds.

We are capable of offering you tight tolerancedmetal parts in materials such as stainless steel, carbon steel, aluminum and copper alloys.

PROGRESSIVE STAMPING

AUTOMATIC TRANSFER STAMPING

ASSEMBLY & SECONDARY OPERATIONS

After stamping, the parts can be treated and operated by more value added services like:

- Welding

- Deburring

- Cleaning

- Tumbling

- Passivation

- Plating

- Painting

- Threading

- Riveting

- Silk printing

So just leave the prints or samples to us, we can deliver the final products to you with one stop service.